The Luke Hand Project: From Disabled to Super-Abled

Shalom’s infant son, Theo, has a limb difference - he was born with no right hand. The technical term is a congenital transradial amputation. Shalom - an Experience Designer at Autodesk’s Pier 9 Workshop - and his wife ultimately came to see that this offered an amazing opportunity to be of service, not only to their own son, but potentially also to the many people throughout the world who have upper limb differences. An opportunity to assemble a team to create the labor of love that is the The Luke Hand.

Theo’s case is far from isolated. There are around two million people globally who have one or no hands, due either to congenital or traumatic amputations. Most currently available, affordable prosthetic or bionic devices are inadequate in terms of comfort, fluid control, and dexterity. On top of that, children with limb differences require updated prostheses more frequently due to their rapid growth.

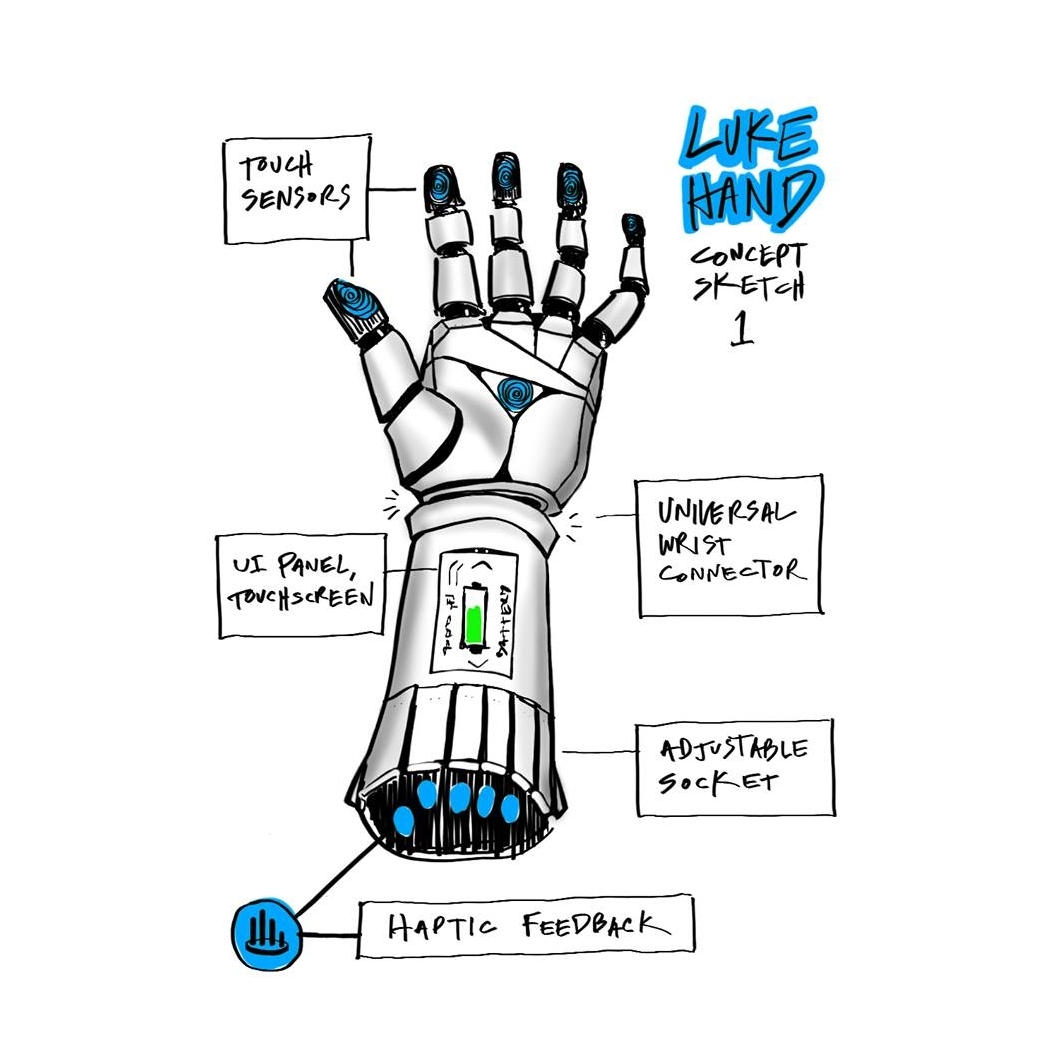

So, what's the Luke Hand?

Inspired by the sci-fi story of Luke Skywalker's robotic hand (which replaced his severed hand in the Star Wars saga), a team of experts has assembled to create an open source bionic hand with the functionality of a human hand, designed for a four year old, within four years. The Luke Hand is also the name of the nonprofit organization that's been formed to design and build this device.

What's the Luke Hand's mission?

First, to create an open source bionic hand with the functionality of a human hand, within four years, sized for a four year-old. And then to scale up the project, to create the greatest positive impact for people with limb differences around the world.

Why create the Luke Hand?

To help people with hand amputations transition from disabled to superabled.

Why create the Luke Hand?

Because it should already exist! The Luke Hand will be life-changing for people with hand amputations. Perplexingly, despite the high-tech era in which we live, technology remains sadly deficient in the field of prosthetics - so deficient, in fact, that a large percentage of people who have been fitted for prosthetic devices don't bother to wear them.

What is currently available?

Prosthetic hands that offer limited functionality have been available for thousands of years (read more). And modern fabrication methods such as 3D printing has made it easier than ever to create these devices. In terms of devices that offer high functionality, DARPA has developed a sophisticated bionic hand, as have companies like ottobock and several others - many of which you can see here - but no one has brought to market an affordable bionic hand for children that matches the functionality of a human hand. Perhaps no one believes that there would be enough profit in this venture. Therefore, The Luke Hand is taking a radically different approach.

Shalom and Theo.

What's the Luke Hand's plan?

Our plan is to develop a bionic hand free of the requirement to create profit. To do this, we plan to have our R&D costs paid for by charitable donors and foundations. We will stretch these dollars as far as possible and maximize the project’s brainpower by hosting global hackathons and guided development programs at universities throughout the world. Not needing to recoup our R&D costs from the price of the device, the cost of The Luke Hand will simply be the price of materials, labor, shipping, and tax. By open sourcing all of our IP, we will enable people from around the globe to both contribute to its design and benefit from its development.

Phase 1 entails creating The Luke Hand for Theo when he’s four years old, publishing and refining our IP on open source repositories throughout the process of development.

Phase 2 entails scaling up the business and creating larger models that fit older children, teens, and adults, so that anyone who needs a Luke Hand can have one, at the lowest possible cost.

Who are you, and how are you going to do this?

I have the good fortune of being an Experience Designer at one of the world's leading industrial-strength creative workshops for design & fabrication - Autodesk Pier 9. My wife is an expressive arts teacher with a deep knowledge of somatics.

Obviously, this mission is far too vast for me to accomplish alone. The only way to create The Luke Hand is through skillful teamwork. Fortunately, many of my colleagues at Autodesk are cutting-edge robotics experts, mechanical CAD engineers, software and firmware developers, fellow XD’s, 3D printing gurus, and more. And my greater professional community includes bionics engineers, prosthetics experts, industrial designers, electrical engineers, lawyers, doctors. And I'm delighted to say that people from all these fields have volunteered to team up and help the cause.

The first major step forward for The Luke Hand was to assemble a dream team of advisors. The first person to become an advisor was the former lead engineer of DARPA’s Revolutionizing Prosthetics 2009 bionic arm, Dr. Adam Arabian of Seattle Pacific University. Having already built the world’s most advanced bionic hand, his addition to the team was a huge boost for our project.

The director of Autodesk’s Applied Research Lab, Maurice Conti, also became an advisor (read about the innovations in robotics happening at this lab). Plus Lynelle Cameron, the CEO of Autodesk Foundation, which supports the design and creation of innovative solutions to the world’s most pressing challenges. Plus Scott Summit, a leading Industrial Designer who has helped lead the effort to create Beautiful Artificial Limbs. Plus Andreas Bastian, the Technical Director of e-NABLE, which creates low-cost 3D printed prosthetic limbs for people with limb differences, and who happens to be my teammate on Autodesk’s Integrated Additive Manufacturing team. Plus Maria Guidice, Autodesk’s VP of Experience Design. Plus Teg Grenager, an entrepreneur who served as VP of Product at a successful tech company in Silicon Valley.

You’re called yourself a “power user, fan, advocate” of ReMake! Talk about the tools you’re using with the Luke Hand project and how?

I’m a fan and advocate of ReMake because it makes it the process of creating incredibly detailed 3D meshes super simple. My job at Autodesk involves working with 3D meshes and 3D printing, and I’ve never gotten tired of it.

If I’m a ReMake power user, that’s because I use it so much. Actually, using ReMake’s photogrammetry tools is something I love to do while I’m traveling on vacation. My wife, Theo, and I recently visited her hometown of Darmstadt, Germany, and while we were there, I shot numerous photo arrays that I fed into ReMake to create many beautiful 3D models. Several of these models can be viewed on my ReMake Gallery.

Talk about the tools you’re using with the Luke Hand project and how?

ReMake was the first tool I used in the process, because I wanted to start with a real live hand reference at the proper scale. So I asked for a friend’s permission to shoot a photo array of her five year old son’s hand. [Technical note: I included a quarter in the scene, which served as a size reference (US quarters are 24.26mm wide).]

I fed these photos into ReMake, and got a beautiful base mesh for The Luke Hand in return, which serves as the form factor reference. [Although we’re making this for Theo when he’s four, the hand will be the size of a five year old’s hand, which will give him room to grow into it. The socket of The Luke Hand will be designed so that it can comfortably conform to his residual limb when he’s four years old.] I’m so grateful to have powerful and indispensable tools, such as ReMake, so easily accessible, which help simplify and streamline the process of a task that’s as ambitious and complicated as creating a bionic hand.

You made a great video for the Autodesk Global Hackathon about the use of VR in bionics. Why is VR important to bionics and specifically to the Luke Hand project?

Thanks! As I’ve learned from personal experience, building hardware is hard. Simulating before building makes it easier. And when you simulate in VR, you get the benefit of the most immersive, realistic environment that we can possibly create, currently. This creates an optimal environment to learn how to use a bionic hand, and furthermore, to train it to be as responsive as possible to the commands of the muscles of the residual limb. We’re using machine learning to develop an intelligent control system that improves with use – the brains of The Luke Hand. Our first hackathon, called VR Bionics, was focused on creating the foundation of this intelligent control system, and posting all of our code on GitHub, open source. [The code will be coming soon - our developers are currently polishing up and documenting their code before posting it.]

What’s in the pipeline for Luke Hand?

The Luke Hand is about to launch a guided development program at Seattle Pacific University, where Adam Arabian teaches. This program will run for half a year, and will focus on developing the needed mechanical components, the muscles, as it were, for The Luke Hand’s brain.

We’re also planning additional hackathons and guided development programs. And we’ve been invited to present the results of our VR Bionics work to a team at Stanford University that’s focused on VR and computer science.

Finally, once we complete our 503c(3) registration (which is currently in progress), The Luke Hand will apply to Autodesk Foundation and other philanthropic foundations for funding.

Sounds great. How can I help?

Donate to the fundraising campaign

Subscribe to The Luke Hand’s newsletter: http://bit.ly/lukehand-subscribe

Sign up to volunteer your skills: http://bit.ly/TLH-Questiionnaire

Follow us…

On Wevolver: https://www.wevolver.com/shalom.ormsby/the-luke-hand/

On GitHub: https://github.com/TheLukeHand

On Facebook: https://www.facebook.com/thelukehand

On Twitter: https://twitter.com/thelukehand

On Pinterest: https://www.pinterest.com/thelukehand/

- Spread the word - tell people who might like to help the cause